Why Lead-Free Solder is the Future of RC Performance

By Team Exalt Tech Blog

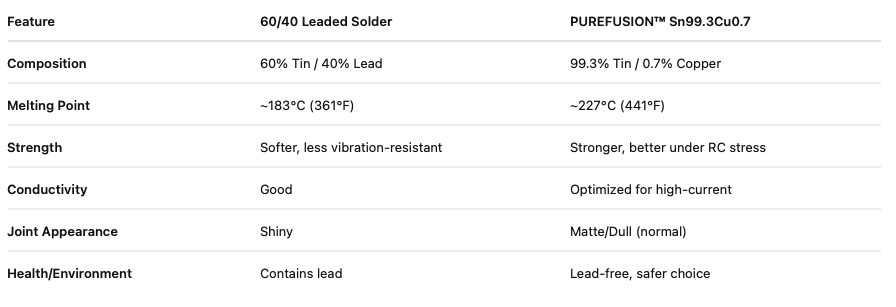

For decades, most RC racers have used 60/40 leaded solder (60% tin, 40% lead) because it’s cheap, easy to melt, and leaves a shiny finish. But “easy” doesn’t always mean “better.” In fact, when you look at the science of conductivity, strength, and durability, the picture changes dramatically.

Team Exalt’s PUREFUSION™ Sn99.3Cu0.7 Lead-Free Solder is engineered to outperform 60/40 in the places that matter most — current handling, joint strength, and long-term reliability under racing conditions. Let’s break it down.

1. Electrical Conductivity: Resistance = Heat = Lost Power

-

60/40 solder: While conductive, it has higher resistance than high-purity alloys because of the lead content, which dilutes tin’s natural conductivity. Under high current (like 100+ amps in modern RC ESCs and batteries), even small resistance increases translate into wasted power and heat buildup.

-

Sn99.3Cu0.7 solder: With nearly pure tin and a small copper content, it achieves lower electrical resistance, meaning more current gets to the motor and less turns into wasted heat. This is why racers using PUREFUSION see cooler running connectors and wires after long mains.

Takeaway: A shiny 60/40 joint may look good, but it’s actually a bottleneck under high-current RC loads. PUREFUSION flows power more efficiently.

2. Mechanical Strength: Surviving Vibrations and Crashes

-

60/40 solder: Lead makes the joint softer. This is fine for home electronics, but in RC racing, connectors are exposed to constant vibration, crashes, and repeated heating cycles. 60/40 joints can fatigue and crack over time.

-

Sn99.3Cu0.7 solder: Copper fortifies the bond, creating a stiffer, stronger joint that resists cracking even under heavy stress. The result? Fewer failures at the connector and more confidence when running high-power setups.

Takeaway: Stronger joints mean longer-lasting builds and less mid-race solder failures.

3. Melting Point: Why Higher is Better in RC

-

60/40 solder: Melts at ~183°C (361°F). Easy to work with, but here’s the problem: ESCs, motors, and batteries in RC can generate heat well above 150°C under extreme load. That means 60/40 joints are closer to their melting/failure range during hard runs.

-

Sn99.3Cu0.7 solder: Melts at ~227°C (441°F). This buffer is huge. Even if your system is cooking, your joints stay solid and structurally safe.

Takeaway: With RC electronics pushing harder every year, higher-temp solder gives you a safety margin 60/40 can’t match.

4. Appearance vs. Reality

One of the biggest reasons racers cling to 60/40 is the shine. Leaded solder cools to a bright, mirror-like finish that “looks perfect.”

But:

-

Shine ≠ strength.

-

Shine ≠ conductivity.

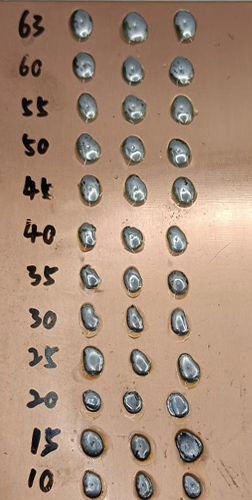

Lower the Tin Content the higher the required operating Temperature

Lead-free solder like PUREFUSION naturally looks duller, but that dull surface hides a stronger, more reliable joint. The racing industry is catching up to what aerospace and automotive electronics already know: dull is durable.

5. Health & Safety — The Overlooked Factor

While many racers focus on performance, the truth is lead exposure is a serious issue. Every time you solder with 60/40, you release toxic fumes and handle lead directly. Over time, this isn’t just an inconvenience — it’s a health hazard.

PUREFUSION is 100% lead-free, safer to use at the track, around kids, and in your workshop.

Best Practices for PUREFUSION Success

-

Iron Temp: Run hotter than you would with 60/40 — 370–400°C (700–750°F).

-

Flux Use: Always apply flux for large-gauge wires (like 10–12 AWG). It makes wetting fast and reliable.

-

Pre-Tinning: Always tin both the wire and connector before joining.

-

Timing: Don’t linger — apply heat, let it flow, and pull away.

-

Don’t Judge by Shine: Matte finish = race-ready joint.

Why PUREFUSION Wins on Race Day!

-

Cooler-running electronics under load

-

Stronger vibration-resistant joints

-

Higher temperature safety margin

-

Long-term reliability (no cracked solder)

-

Lead-free and safer for you, your pit, and the environment

Final Word:

60/40 Is Old School. PUREFUSION Is the Future.

60/40 had its time. For racing applications, though, it’s outdated. High-current RC systems demand stronger, safer, and more reliable connections. PUREFUSION Sn99.3Cu0.7 delivers exactly that.

When a race is on the line, would you rather trust “easy and shiny” — or strong, efficient, and proven?

Upgrade to Team Exalt PUREFUSION™ today. Because in RC racing, your power is only as strong as your connections.

Head-to-Head: 60/40 vs. Sn99.3Cu0.7

PUREFUSION: Because in racing, every connection counts.

Click Here and Try for Yourself!

Inside Exalt

-

Why Lead-Free Solder is the Future of RC Performance

Aug 26th 2025By Team Exalt Tech Blog For decades, most RC racers have used 60/40 leaded solder (60% tin, 40% le

-